ThermoNoxilo - Silo treatment

ThermoNoxilo - Silo treatment

Pest control + hygiene improvement in silo bins

In a silo treatment one or more ThermoNoxilo silo heaters are placed in e.g. a flour silo for pest control or hygienic improvement (mold, caking etc.). Only the air in the silo is continuously circulated and heated to a lethal temperature of approx. 55°C. The period of one treatment including the heating phase and the temperature holding phase is about 48 hours.

.

.

Silo heater: ThermoNoxilo SO 18

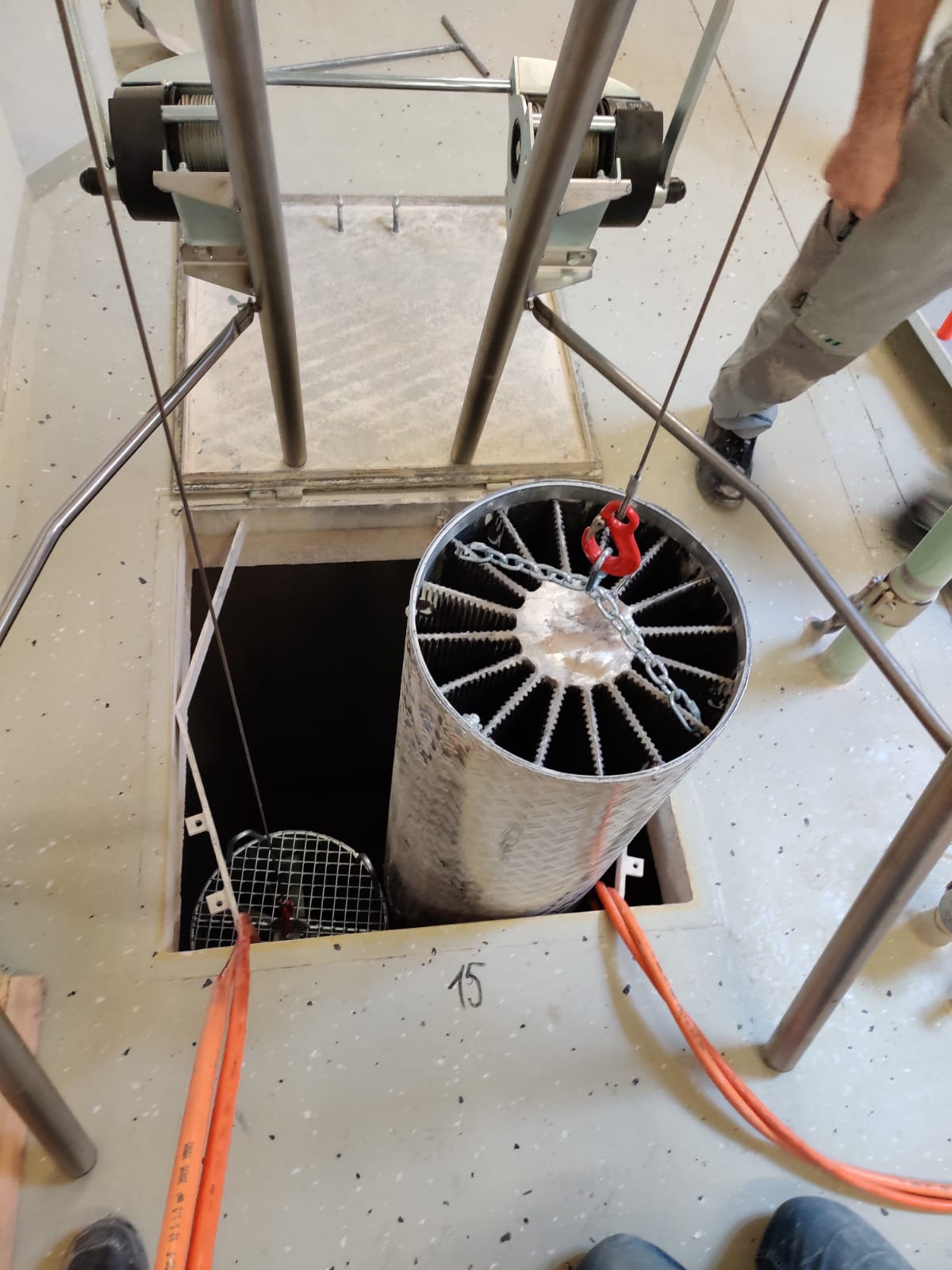

The ThermoNoxilo SO 18 silo heater is entered into the silo via the manhole and by using a specially

designed silo winch.

Technical data:

- Robust aluminum cylinder for positioning inside the silo

- 18 kW heating power + powerful axial fan

- External control cabinet for positioning outside the silo

- Temperature control by automatic cycling

Optional: Silo winch

With the silo winch two units can be positioned independently inside the silo. All components can be disassembled into manageable sizes and stored on a pallet together with two pieces of ThermoNoxilo.

Safety:

In a flour or even grain silo the occurrence of dangerous, explosive atmosphere cannot be excluded. Such closed bins are classified according to explosion protection with ATEX zone 21. The ThermoNoxilo and the silo winch are safely designed for your application and tested by DEKRA. In addition to the ATEX certification (type examination) the ThermoNoxilo also has the internationally common IECEx certification.